Dished Heads

Bending

Tanks

Heat Treatment

GBS Pressure Vessels CO.

GBS is located in Istanbul; It is a company that produces domes, compressed air tanks, various LPG storage tanks, autogas storage tanks and refrigerant gas tanks.

The company's production experience; The camber goes back to 1945 and the pressurized tank production goes back to 2000.

We continue production in our new factory with our renewed machinery park and our well-trained and very experienced employees in metal forming and pressure vessels.

CAD/CAM supported design and equipment play an important role in our production and quality processes.

Our optimized production line and welding equipment enable our talented staff to keep production quality at the highest level.

On Time Delivery

Smart Technology

Quality and Economical

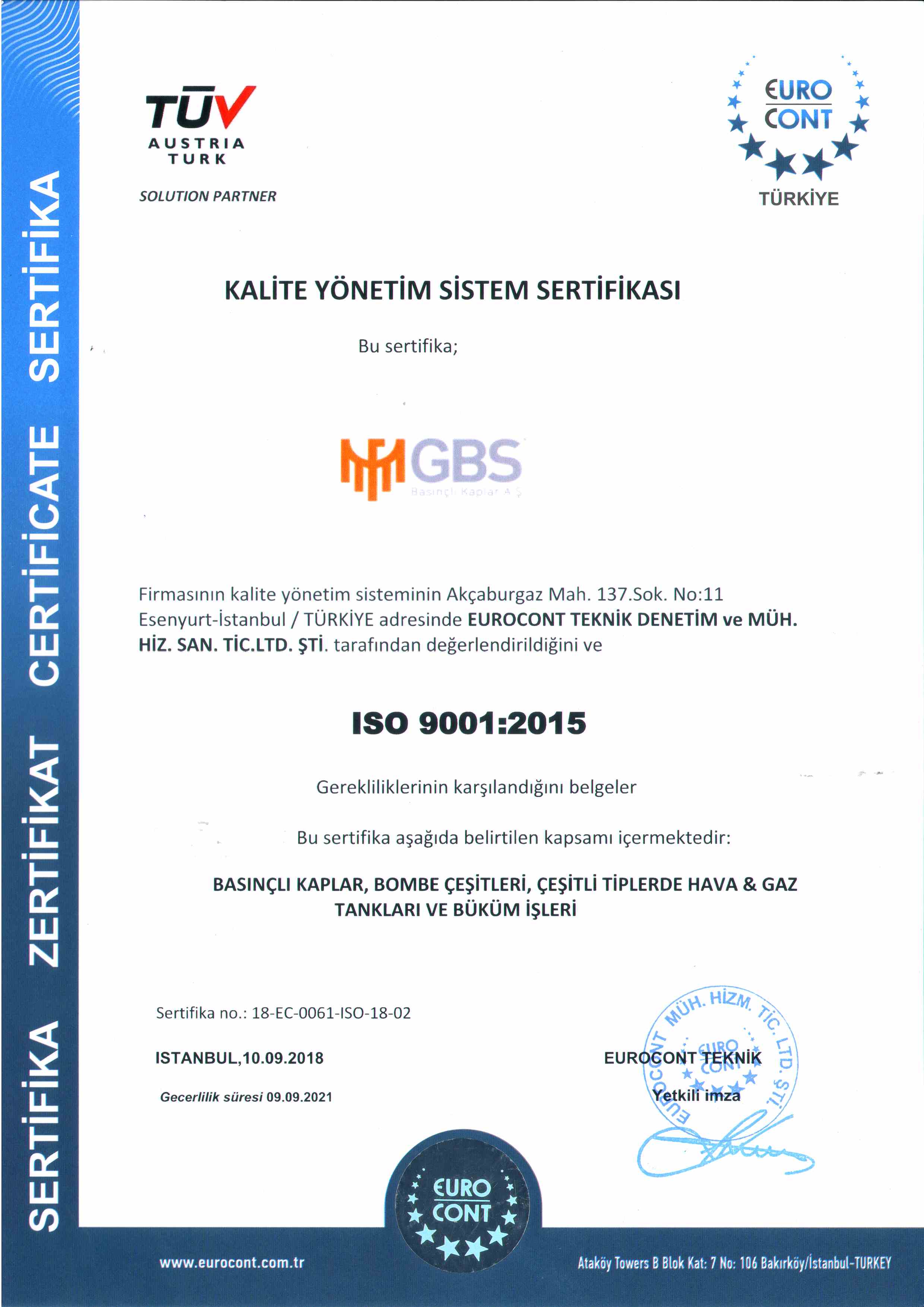

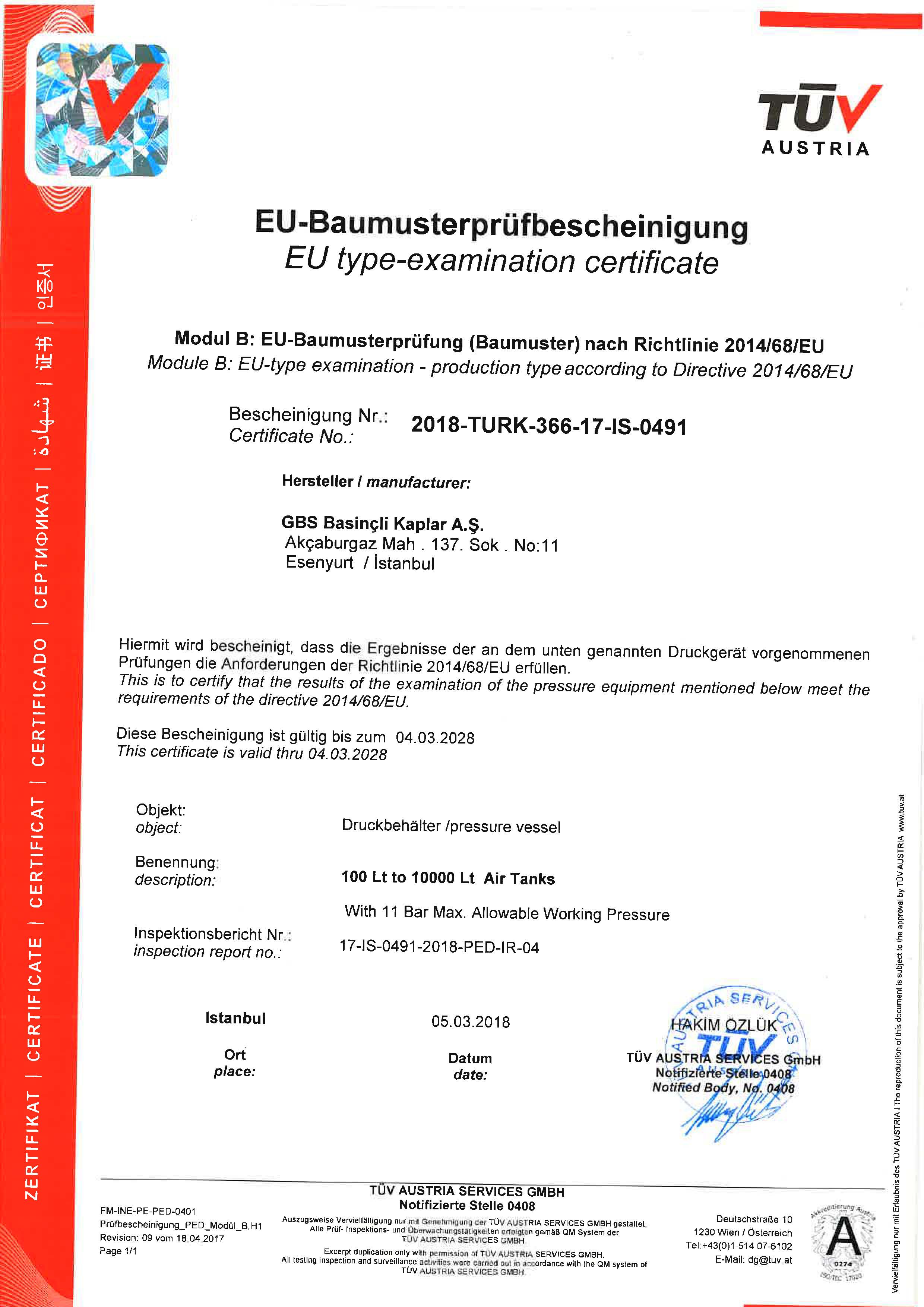

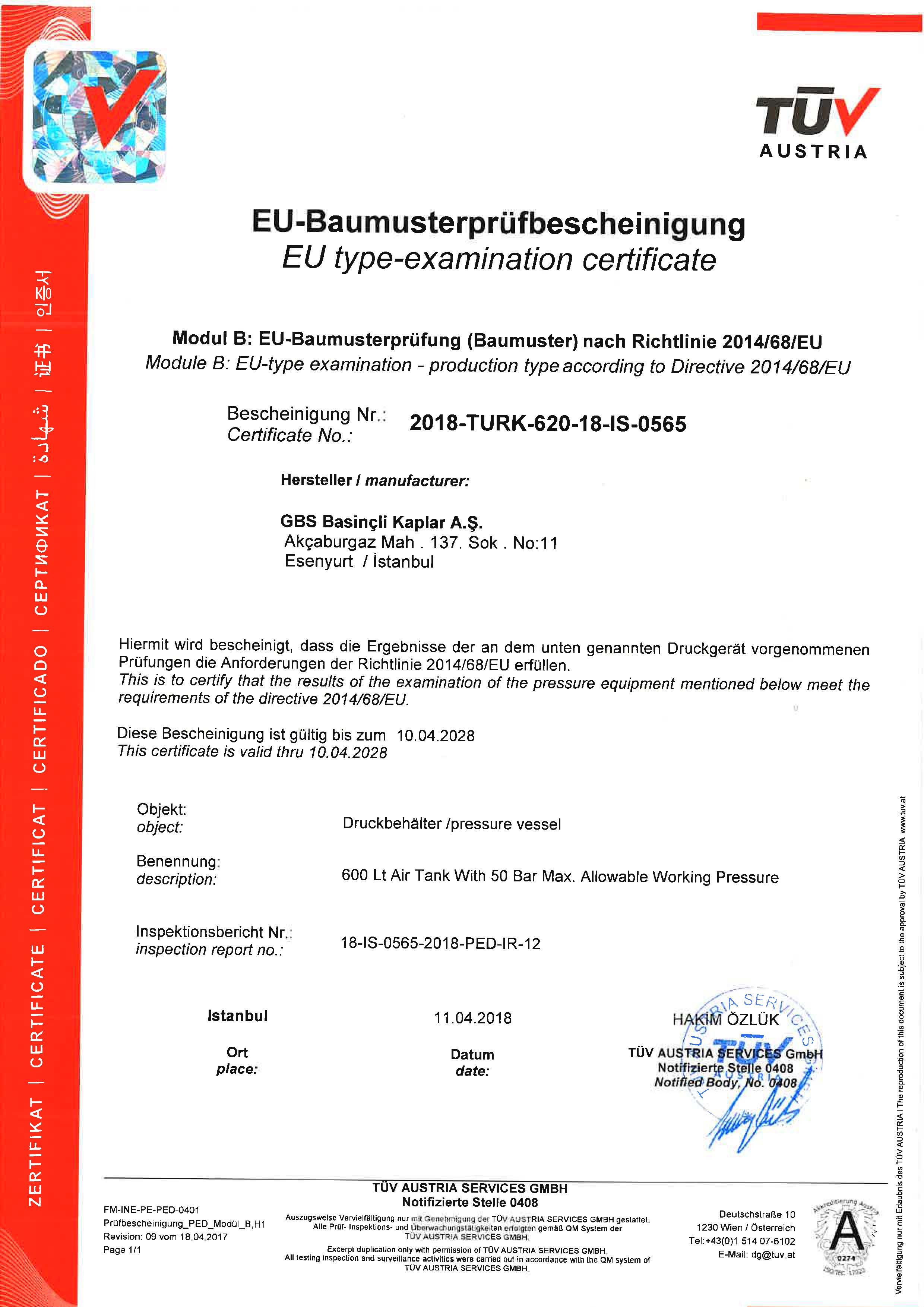

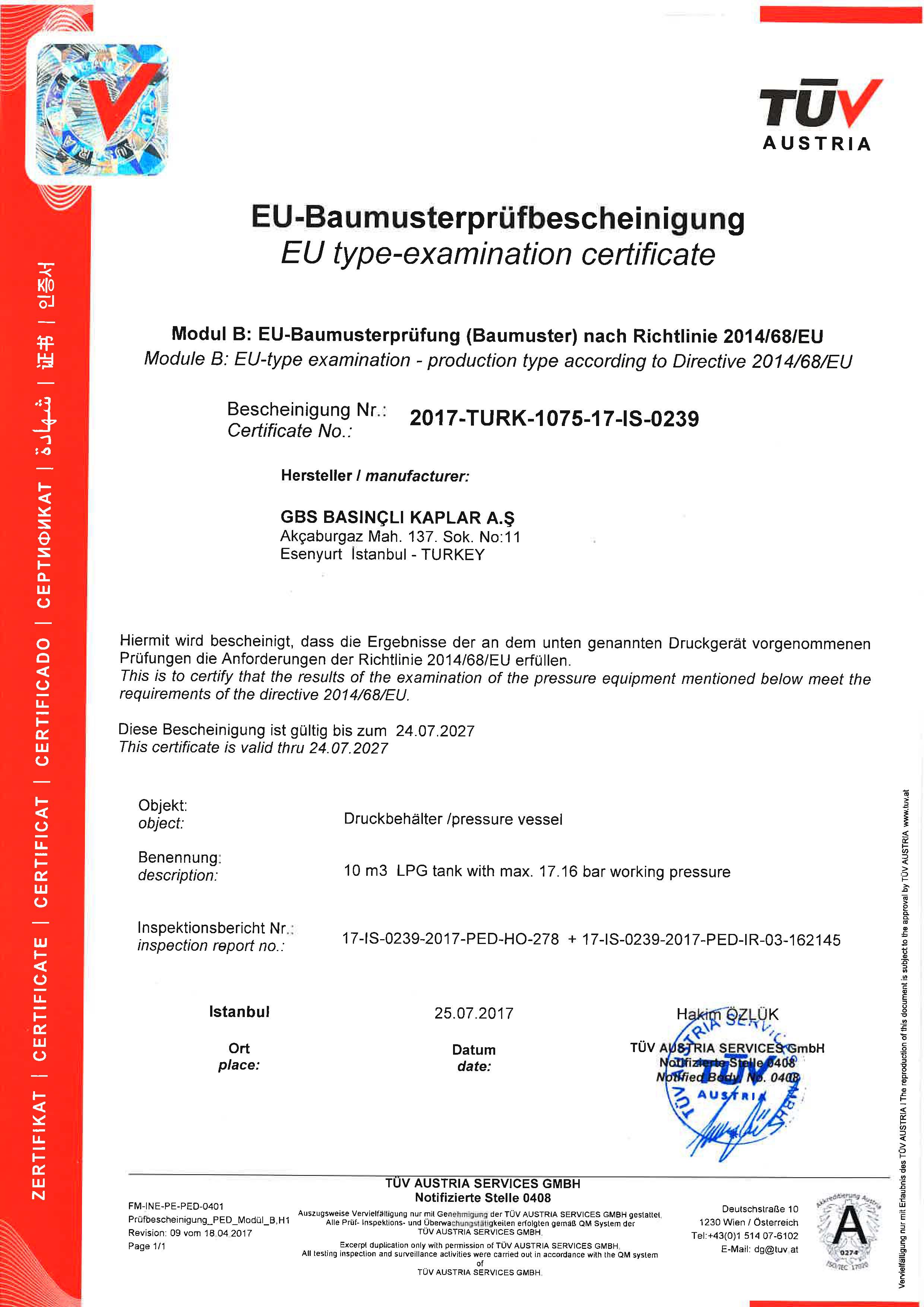

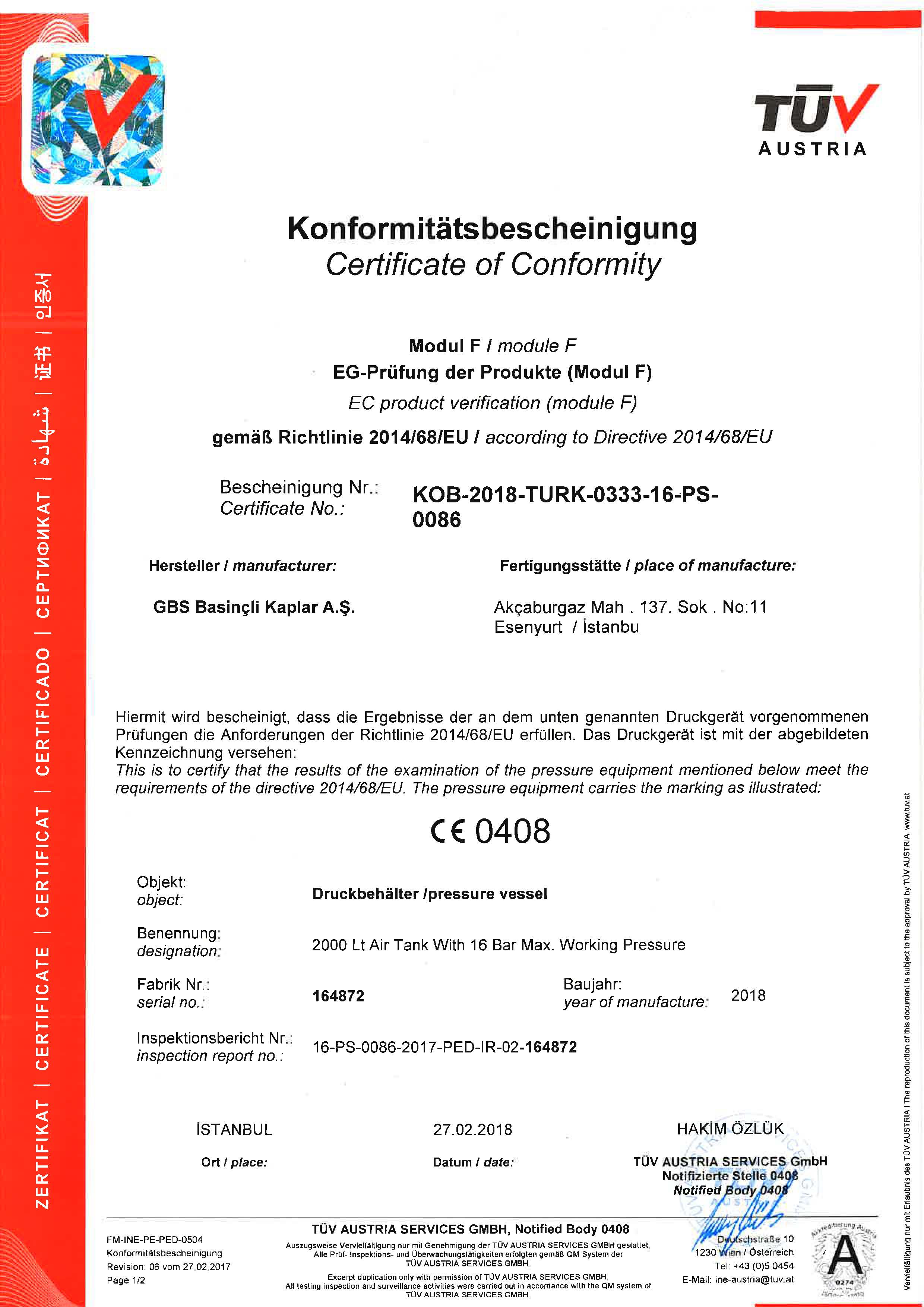

Certificates

Certificates

Certificates

Certificates

Certificates

Certificates

Certificates

Certificates

Certificates

Certificates

Tank Production

Güven Bombe: Expert in Compressed Air Tank Production

Compressed air systems are critical in many industrial applications. Güven Bombe is a company that has proven itself in the sector with its deep technical knowledge and expertise in the field of compressed air tank production. Its vast experience in producing high-quality, safe and durable compressed air tanks has been shaped to best meet the needs of industrial enterprises.

Güven Bombe's expertise is evident not only in product quality, but also in the meticulousness it shows at every stage of the production processes. Our company designs and produces world-class compressed air tanks suitable for all kinds of industrial facilities. Our products, which have international certificates such as TSE, CE and ISO, are produced to meet safety and efficiency requirements at the highest level.

Why Güven Bombe?

- 1. High Safety Standards: Compressed air tanks are critical equipment operating under high pressure. Güven Bombe guarantees maximum safety in every product with the state-of-the-art equipment and high engineering skills it uses in its production.

- 2. Expert Technical Staff: Our expert team, which accurately analyzes all the requirements of the sector, has a constantly evolving vision to produce all kinds of technical solutions.

- 3. Customized Solutions: We offer customized compressed air tank solutions to suit the specific needs of different industrial sectors. We provide reliable products for all sectors.s

- 4. Quality and Performance: Our products are produced by prioritizing not only safety but also performance. Long-lasting, low-maintenance and efficient tanks ensure uninterrupted operation of your business.

Our Tank Types

- 1. Horizontal Air Tanks

- 2. Vertical Air Tanks

- 3. Horizontal LPG Storage Tanks

- 4. Vertical LPG Storage Tanks

- 5. LPG Autogas Storage Tanks

Güven Bombe is always one step ahead to contribute to your production with the experience it has gained in high pressure air tank production. You can benefit from Güven Bombe's expert solutions to increase the efficiency and ensure the security of your business.

Please contact us for our products.

Dished Heads

GBS produces curves in accordance with international norms with cold and hot forming methods and CNC-supported manipulator-controlled hydraulic curve presses, automatic edge plastering machines and plastering presses. It carries out its production by processing the materials supplied by the customer or by itself.

Review

Bending

GBS Profile Bending bends all profiles in the Manufacturing program according to the specified minimum inner diameters.

The profile to be bent must have the desired diameter and radius, and the material to be bent must have a homogeneous structure and be suitable for cold forming in order to prevent possible breakages during shaping.

Review

Tanks

Our standard product range ranges from 100-20,000 liters of volume and 8-40 bar pressure, horizontally or vertically. Our production is carried out in accordance with EN 13445, AD 2000, EN 286 and ASME sec VIII div 1 and is in compliance with the relevant European Directive 97/23/EC and CE certified.

Review

Heat Treatment

The natural complement of cold forming, GBS's heat treatment furnaces are TÜV approved. It is capable of meeting all the requirements set by international standards for Austenitic stainless, Carbon Steel, Duplex, Super Duplex stainless grades, nickel alloys and low alloy carbon steel. All our heat treatment furnaces are checked according to ASTM A 991 - SAE AMS 2750-ISO 17763-EN 746 standards and the calibrations of the furnaces are carried out by internationally accredited organizations.

Review

Company Promotion Video

You can contact our authorized team member regarding the issue.

.png)